what is the name of the scale used to determine hardness

Home » Minerals » Mohs Hardness Scale

Mohs Hardness Calibration

A rapid hardness test for field and classroom use

Article by: , PhD, RPG

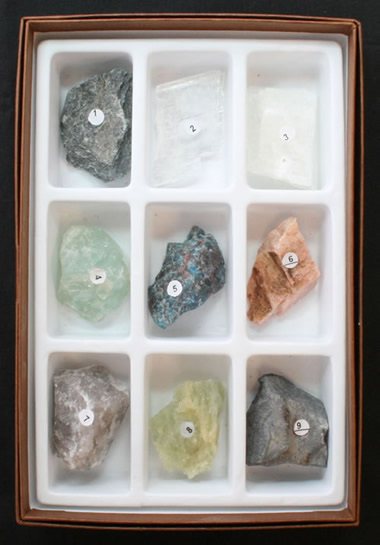

Mohs Hardness Kit: A laboratory Mohs Hardness Scale kit containing: (1) talc; (2) gypsum; (3) calcite; (4) fluorite; (v) apatite; (vi) orthoclase; (7) quartz; (8) topaz; and (9) corundum. Diamond is not included in most kits to keep the cost downwards. As well a diamond specimen would be then small that information technology would need to be mounted in a handle to be useful. Purchase a Mineral Hardness Kit.

What is Mohs Hardness Scale?

One of the most important tests for identifying mineral specimens is the Mohs Hardness Examination. This examination compares the resistance of a mineral to being scratched by ten reference minerals known as the Mohs Hardness Scale (see tabular array at left). The test is useful because most specimens of a given mineral are very close to the same hardness. This makes hardness a reliable diagnostic property for most minerals.

Friedrich Mohs, a German mineralogist, developed the scale in 1812. He selected 10 minerals of distinctly different hardness that ranged from a very soft mineral (talc) to a very hard mineral (diamond). With the exception of diamond, the minerals are all relatively common and easy or inexpensive to obtain.

Making Hardness Comparisons

"Hardness" is the resistance of a material to beingness scratched. The test is conducted by placing a sharp betoken of ane specimen on an unmarked surface of another specimen and attempting to produce a scratch. Here are the 4 situations that you might observe when comparing the hardness of two specimens:

1. If Specimen A can scratch Specimen B, then Specimen A is harder than Specimen B.

two. If Specimen A does not scratch Specimen B, then Specimen B is harder than Specimen A.

3. If the two specimens are equal in hardness and then they volition be relatively ineffective at scratching one another. Small scratches might exist produced, or it might be hard to determine if a scratch was produced.

four. If Specimen A can exist scratched by Specimen B but it cannot be scratched past Specimen C, then the hardness of Specimen A is betwixt the hardness of Specimen B and Specimen C.

Mohs hardness exam: When conducting the test, place the unknown specimen on a tabular array peak and firmly concord information technology in place with one manus. So identify a point of the reference specimen against a flat, unmarked surface of the unknown specimen. Press the reference specimen firmly confronting the unknown, and deliberately elevate information technology across the flat surface while pressing firmly. To avoid injury, drag the known specimen away from your torso and parallel to the fingers that are holding the unknown specimen.

Mohs Hardness Testing Process

- Begin by locating a smooth, unscratched surface for testing.

- With one mitt, hold the specimen of unknown hardness firmly against a table top and then that the surface to exist tested is exposed and accessible. The table top supports the specimen and helps you agree it motionless for the test. (If you lot are doing this test at a prissy desk-bound yous may want to become a thick piece of paper-thin, a thick rubber pad, or a sheet of some other material to protect the surface from being scratched.)

- Hold i of the standard hardness specimens in the other hand and place a indicate of that specimen against the selected flat surface of the unknown specimen.

- Firmly press the betoken of the standard specimen against the unknown specimen, and with firm force per unit area, drag the bespeak of the standard specimen across the surface of the unknown specimen.

- Examine the surface of the unknown specimen. With a finger, brush away any mineral fragments or powder that was produced. Did the exam produce a scratch? Be conscientious non to misfile mineral powder or residue with a scratch. A scratch will exist a distinct groove cut in the mineral surface, not a mark on the surface that wipes away. Utilise a hand lens to get a practiced look at what happened.

- Comport the test a second time to ostend your results.

Mohs Hardness of Common Minerals

Mohs Hardness Testing Tips

- A list of minerals in order of hardness can be a handy reference. If you determine that a specimen has a hardness of Mohs four, you lot tin speedily get a list of potential minerals.

- Practice and experience volition improve your abilities when doing this test. Y'all volition go faster and more confident.

- If the hardness of the unknown specimen is about 5 or less, you should be able to produce a scratch without much exertion. However, if the unknown specimen has a hardness of most vi or greater, so producing a scratch will require some force. For those specimens, hold the unknown firmly confronting the tabular array, place the standard specimen confronting it, press firmly with determination, then property pressure level slowly drag the standard specimen beyond the surface of the unknown.

- Don't be fooled past a soft standard specimen producing a mark on a difficult unknown. That mark is like what a piece of chalk produces on a blackboard. It volition wipe off without leaving a scratch. Wipe your finger across the tested surface. If a scratch was produced, there will be a visible groove. If marks wipe away then a scratch was not produced. Cheque for the scratch with a hand lens.

- Some difficult materials are as well very brittle. If one of your specimens is breaking or crumbling rather than scratching, you will have to be very careful while conducting the exam. Testing tiny or granular specimens can be difficult.

- Some specimens contain impurities. If the results of your examination are non visibly conclusive, or if the information from your exam does not conform with other backdrop, practice not hesitate to do the exam again. Information technology is possible that a pocket-size piece of quartz (or some other impurity) was embedded in 1 of your specimens.

- Don't be wimpy! This is a very mutual problem. Some people casually rub one specimen back and forth against some other and then look for a mark. That is non how the test is done! Information technology is washed with a single, slow, determined motion, with business firm pressure, with the goal of cut a scratch.

- Be careful! When nosotros exam we advisedly hold the rock existence tested then that if the pick slips it will non punch a hole in our finger.

- When we exercise the hardness test, we place a thick sheet of heavy paper-thin or a rubber pad on our table to protect its surface from being scratched.

- This test should be done on a lab table or work bench with a durable surface or a protective covering. Don't exercise this type of testing on fine article of furniture.

- Exam tiny particles or grains by placing them between two pieces of an index mineral and scraping them together. If the grains are harder than the index mineral, scratches will be produced. If the grains are softer they will smear.

Hardness of Common Objects

Some people make their ain hardness testing kit using a few common objects. The contents of their kit often include:

| | |

| Fingernail | 2 to 2.5 |

| Copper sheet | 3 |

| Nail | iv to 7 |

| Glass | iv to 7 |

| Knife blade | 5 to 6.5 |

| Steel file | five to 6.5 |

| Streak plate | five to 7 |

| Quartz crystal | 7 |

This field hardness testing kit sounds like a bully thought. These items toll very fiddling, and y'all tin can pull them out of a belt pack and test the hardness of an unknown specimen in under a infinitesimal.

Merely, before you lot make your ain kit, we want you to be aware of something. We checked the hardness values of "mutual field kit" items suggested in three introductory geology textbooks and institute some of them to exist highly variable. The variabilities that we constitute are shown in the accompanying table.

So, if you are going to use mutual items for hardness conclusion, it is highly recommended that you confirm the hardnesses of all items in your kit.

In summary,

Exam the hardness of your common items if yous desire to get adept results when you use them.

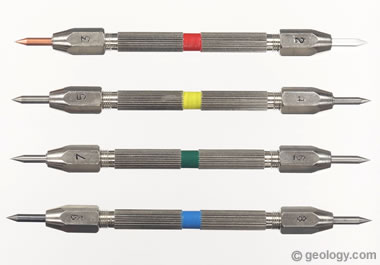

Mohs hardness picks: Hardness picks are easy to apply. They have a brass stylus and an alloy "pick" that is used for hardness testing. Place the abrupt point of a option on your unknown specimen and drag it across the surface. It volition either produce a scratch, slide across the surface, or go out a trace of metal. They are supplied with a hardness of ii (a plastic point), 3 (a copper point), and 4 through nine (carefully selected alloys). They are great for testing small specimens or for testing small grains embedded in a rock. These hardness picks are available in the Geology.com shop.

Hardness Picks

An alternative to using the reference minerals for testing is a set of "hardness picks." These picks accept sharp metal points that y'all can utilize for very accurate testing. The picks allow much more control, and their sharp points can exist used to test small mineral grains in a rock.

The abrupt picks can be used easily and either produce a scratch if they are harder than the specimen existence tested or go out behind a tiny streak of metal if they are softer. Examine the test site with a hand lens to see the results of your exam.

We take used hardness picks and think that they do a great chore. They are easier to employ and more authentic than testing with specimens. They tin be resharpened when they dull. The simply downside is their price (over $100 per prepare).

Harder than Diamond, Softer than Talc?

Diamond is not the hardest substance known, but the materials that are harder are much more rare. Researchers have reported that wurtzite boron nitride and lonsdaleite can exist harder than diamond. [1]

It is unlikely that you will find a mineral that is softer than talc. However, a few metals are softer. These include: cesium, rubidium, lithium, sodium, and potassium. Yous will probably never need to test their hardness. [2]

Mohs - Vickers hardness comparison: This chart compares the hardness of alphabetize minerals of the Mohs hardness scale (an integer calibration) with their Vickers hardness (a continuous scale). Mohs hardness is a resistance to being scratched, while Vickers hardness is a resistance to indentation nether force per unit area. The graph shows the slap-up difference between the Vickers hardness of corundum and diamond - which are only i unit apart on the Mohs hardness scale.

Mohs Calibration of Hardness Compared to Others

When Friedrich Mohs developed his hardness calibration in 1812, very petty information about mineral hardness was available. He simply selected 10 minerals that varied in hardness and arbitrarily placed them on an integer scale from 1 to x. It was a relative scale in which a mineral of unknown hardness could be tested confronting a group of ten index minerals to see where it positioned on the scale.

| | ||

| Mineral | Mohs | Vickers (kg/mm2) |

| Talc | 1 | 27 |

| Gypsum | 2 | 61 |

| Calcite | 3 | 157 |

| Fluorite | 4 | 315 |

| Apatite | 5 | 535 |

| Orthoclase | 6 | 817 |

| Quartz | 7 | 1161 |

| Topaz | 8 | 1567 |

| Corundum | 9 | 2035 |

| Diamond | 10 | 10000 |

The Mohs scale has stood the test of time and has been widely used throughout the world for over 200 years - mainly because information technology is like shooting fish in a barrel-to-do, inexpensive and people quickly understand it. Other hardness tests take been devised but none of them are in as widespread utilise.

A "Mohs hardness" is a relative integer-scale comparing of "resistance to being scratched." Most other hardness scales use "resistance to indentation under a stylus to which a specific amount of force per unit area is practical for a specific length of time." Although these tests differ from Mohs hardness in their procedure, they are all tests of the resistance to atoms being dislodged from their positions by pressure against the surface of a mineral specimen.

One of these scales is the Vickers Hardness Scale. In the Vickers test, the size of the indentation is microscopically estimated and used to calculate a hardness value. The Vickers hardness values class a continuous scale which provides more information nigh the hardness of minerals when compared to the integer values of the Mohs calibration. A table comparing the Mohs scale minerals to their Vickers hardness is shown here along with a graph of the data. The graph shows that in terms of Vickers hardness, the gaps between the integer values of the Mohs scale are non uniform in width. In addition the gaps between minerals of higher Mohs hardness are much broader than those between the softer minerals. In terms of Vickers hardness, diamond is enormously harder than corundum.

The best manner to learn virtually minerals is to study with a collection of minor specimens that you can handle, examine, and observe their properties. Inexpensive mineral collections are bachelor in the Geology.com Store.

Hardness Variations in a Single Mineral

Although reference books and websites often list a unmarried hardness for each mineral, many minerals take variable hardness. They have greater or lesser hardness depending upon the direction in which they are being scratched.

A well-known example of a mineral with variable hardness is kyanite. Kyanite often occurs in blade-shaped crystals. These crystals have a hardness of well-nigh five if they are tested parallel to the long axis of the crystal, and a hardness of about vii if they are tested parallel to the brusk axis of a crystal. Why? These unlike directions see dissimilar bonding environments in the kyanite crystal. The bonds that resist scratching parallel to the long axis of the bladed crystal are weaker than those encountered when scratching across the width of the crystal. Intermediate hardnesses are encountered in other directions.

Another instance is diamond. The people who cut diamonds have known most its variable hardness for hundreds of years. They know that parallel to the octahedral crystal faces, a diamond crystal is almost impossible to saw and very difficult to smoothen. The diamond can exist cleaved in this direction by cleaving, and the best method for cutting it in this management is with a light amplification by stimulated emission of radiation. The softest and all-time management to saw or polish a diamond crystal is parallel to its cubic crystal faces. This information is critical knowledge for the craftsmen who plan the design of a faceted diamond. Understanding it and working with it saves time, saves money and creates a ameliorate product with less waste matter.

Weathering can too influence the hardness of a mineral specimen. Weathering changes a mineral's composition, with the weathering product usually softer than the original material. When testing the hardness or streak or other property of a mineral, the best way to test is on a freshly broken surface with expected luster that has not been exposed to weathering.

Most Hardness Tests

The hardness exam developed by Friedrich Mohs was the offset known test to assess resistance of a material to scratching. It is a very uncomplicated but inexact comparative examination. Perhaps its simplicity has enabled it to become the most widely used hardness test.

Since the Mohs Scale was developed in 1812, many different hardness tests have been invented. These include tests past Brinell, Knoop, Rockwell, Shore and Vickers. Each of these tests uses a tiny "indenter" that is applied to the material being tested with a carefully measured amount of force. Then the size or the depth of the indentation and the amount of force are used to calculate a hardness value.

Considering each of these tests uses a different appliance and different calculations, they tin can not be directly compared to i another. So if the Knoop hardness test was done, the number is unremarkably reported equally a "Knoop hardness." For this reason, Mohs hardness exam results should as well exist reported every bit a "Mohs hardness."

Why are there so many different hardness tests? The type of examination used is determined by the size, shape, and other characteristics of the specimens being tested. Although these tests are quite different from the Mohs test, there is some correlation between them. [2]

Hardness, Toughness, and Strength

When testing for hardness, recollect that you are testing "the resistance to scratching." During the test, some materials might fail in other ways. They could break, deform, or crumble instead of scratching. Difficult materials frequently break when subjected to stress. This is a lack of toughness. Other materials might deform or crumble when subjected to stress. These materials lack strength. Always keep in listen that you are testing for the resistance to being scratched. Don't be fooled by other types of failure in the specimen being tested.

Uses for Hardness Tests

The Mohs Hardness Test is almost exclusively used to determine the relative hardness of mineral specimens. This is washed every bit part of a mineral identification procedure in the field, in a classroom, or in a laboratory when easily identified specimens are being examined or where more than sophisticated tests are not bachelor.

In manufacture, other hardness tests are done to determine the suitability of a material for a specific industrial process or a specific end-utilize application. Hardness testing is also done in manufacturing processes to confirm that hardening treatments such as annealing, tempering, work hardening, or case hardening have been done to specification.

| Information Sources |

| [1] Scientists Detect Material Harder Than Diamond - Lisa Zyga, website article on Phys.org, February 2009. [2] Mohs Calibration of Mineral Hardness: Wikipedia article, concluding accessed July 2016. [3] Material Hardness: website article, Center for Avant-garde Life Bike Engineering, University of Maryland, last accessed July 2016. |

Some Notes on Spelling

Mohs Hardness Calibration is named after its inventor, Friedrich Mohs. This means that an apostrophe is non needed when typing the name of the test. "Moh's" and "Mohs' " are incorrect.

Google is actually smart about these names. You can fifty-fifty type "Moe'due south Hardness Scale" as a query and Google knows to return results for "Mohs Hardness Scale." :-)

Find Other Topics on Geology.com:

Rocks: Galleries of igneous, sedimentary and metamorphic rock photos with descriptions. |  Minerals: Information almost ore minerals, jewel materials and rock-forming minerals. |

Volcanoes: Articles about volcanoes, volcanic hazards and eruptions past and present. |  Gemstones: Colorful images and manufactures nearly diamonds and colored stones. |

General Geology: Articles about geysers, maars, deltas, rifts, salt domes, water, and much more! |  Geology Store: Hammers, field bags, hand lenses, maps, books, hardness picks, gold pans. |

|  Diamonds: Learn about the backdrop of diamond, its many uses, and diamond discoveries. |

Source: https://geology.com/minerals/mohs-hardness-scale.shtml

0 Response to "what is the name of the scale used to determine hardness"

Post a Comment